2023-10-30

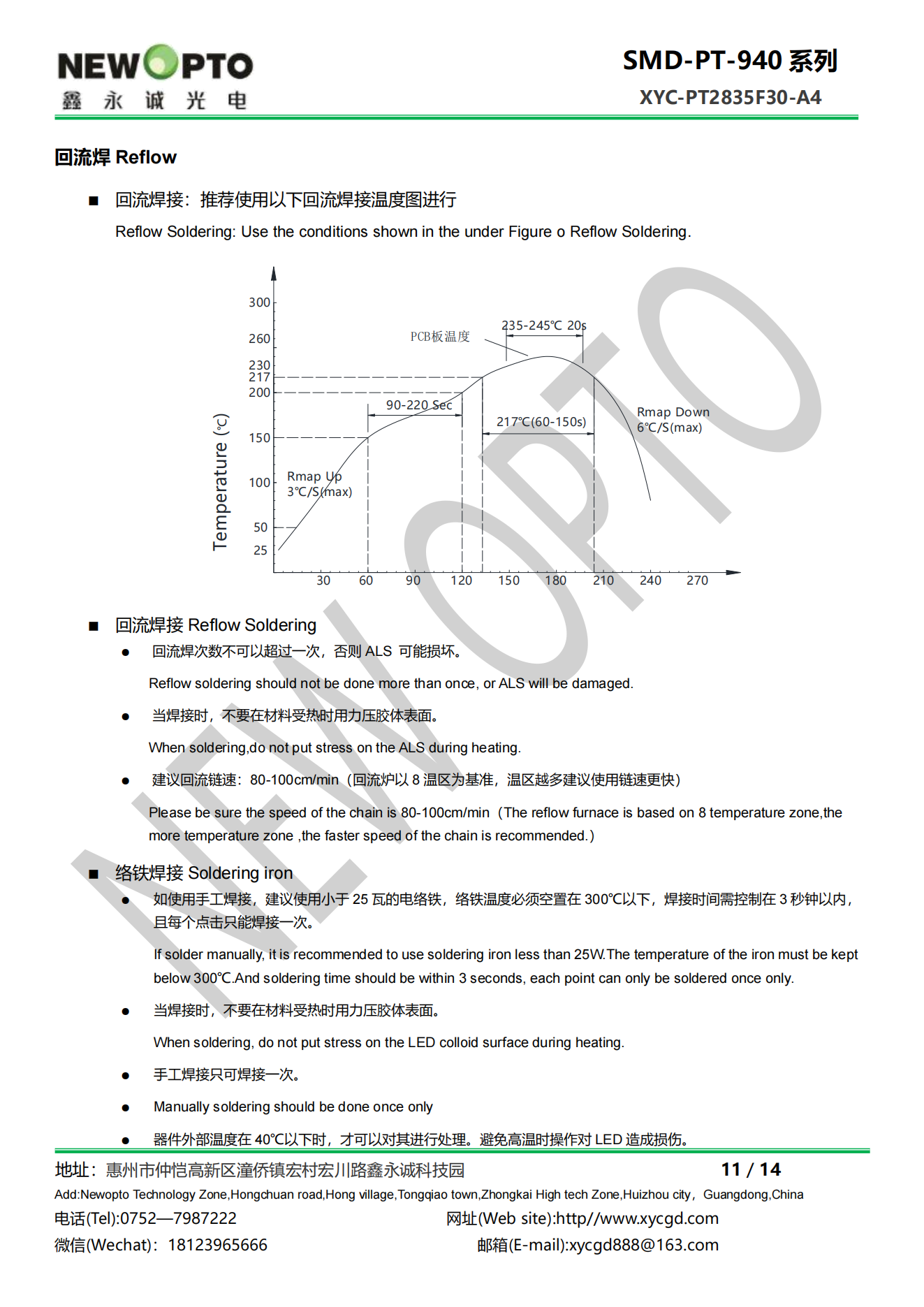

回流焊接 Reflow Soldering

● 回流焊次數(shù)不可以超過一次,否則 ALS 可能損壞。

Reflow soldering should not be done more than once, or ALS will be damaged.

● 當(dāng)焊接時(shí),不要在材料受熱時(shí)用力壓膠體表面。

When soldering,do not put stress on the ALS during heating.

● 建議回流鏈速:80-100cm/min(回流爐以 8 溫區(qū)為基準(zhǔn),溫區(qū)越多建議使用鏈速更快)

Please be sure the speed of the chain is 80-100cm/min(The reflow furnace is based on 8 temperature zone,the

more temperature zone ,the faster speed of the chain is recommended.)

■ 絡(luò)鐵焊接 Soldering iron

● 如使用手工焊接,建議使用小于 25 瓦的電絡(luò)鐵,絡(luò)鐵溫度必須空置在 300℃以下,焊接時(shí)間需控制在 3 秒鐘以內(nèi),

且每個(gè)點(diǎn)擊只能焊接一次。

If solder manually, it is recommended to use soldering iron less than 25W.The temperature of the iron must be kept

below 300℃.And soldering time should be within 3 seconds, each point can only be soldered once only.

● 當(dāng)焊接時(shí),不要在材料受熱時(shí)用力壓膠體表面。

When soldering, do not put stress on the LED colloid surface during heating.

● 手工焊接只可焊接一次。

● Manually soldering should be done once only

● 器件外部溫度在 40℃以下時(shí),才可以對(duì)其進(jìn)行處理。避免高溫時(shí)操作對(duì) LED 造成損傷。